Fabrication and toughness optimization methods of metallic glass films

-

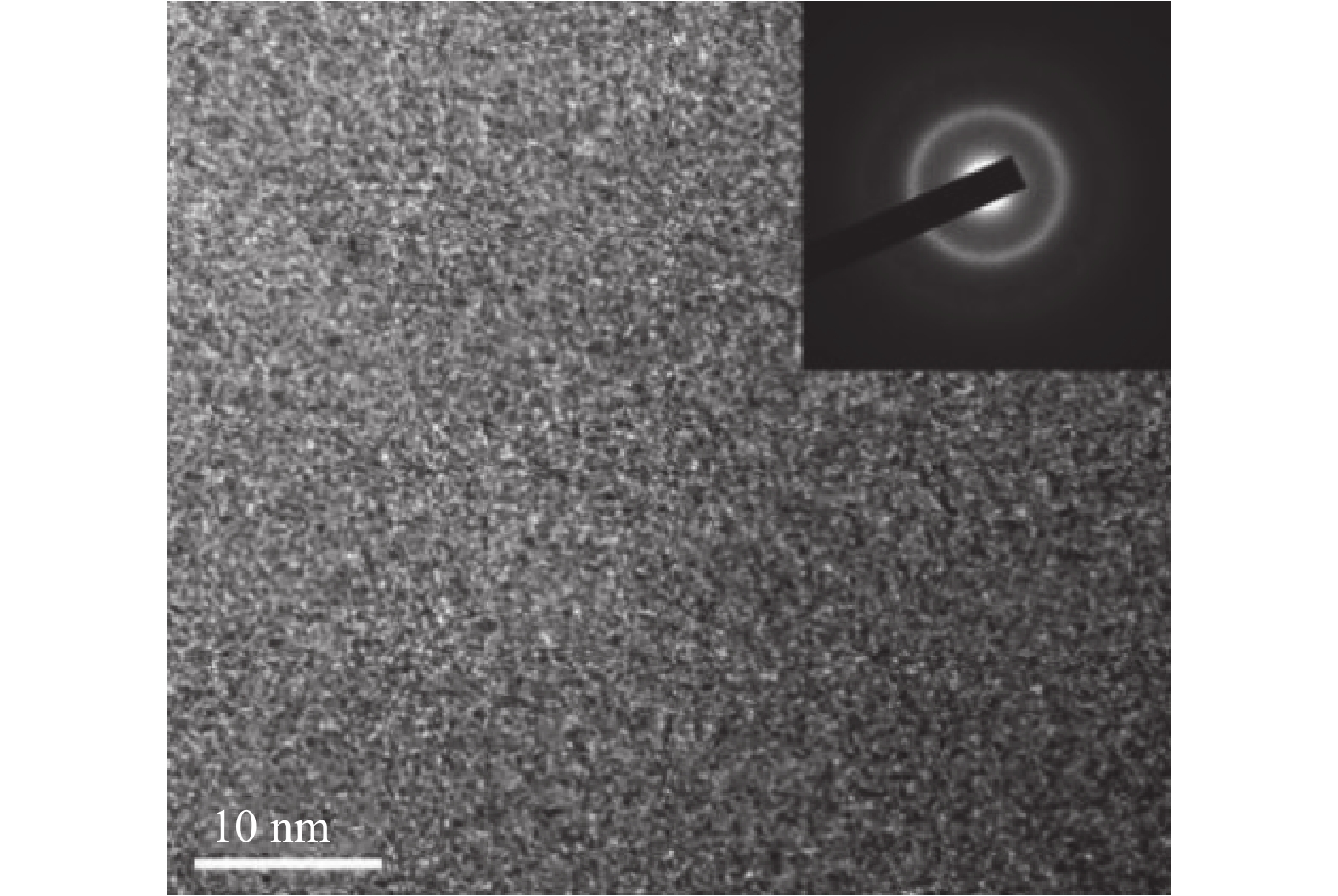

摘要: 由于原子排列短程有序、长程无序,且不具有晶界、位错、第二相等典型晶体缺陷,非晶合金表现出高强度、高硬度以及优异的耐磨性、耐腐蚀性等优异性能。但是非晶合金的本征脆性以及有限的玻璃形成能力极大地限制了其工业应用,非晶合金薄膜的韧性优化便成了当今研究的热点问题。针对非晶合金薄膜的制备以及韧性优化措施进行综述,同时对非晶合金薄膜日后的发展趋势及未来的研究趋势进行了展望。Abstract: Metallic glasses have the advantages of high strength, high hardness, excellent wear resistance and corrosion resistance due to their short range ordered atoms, long range disordered atoms, and the lack of typical crystal defects such as grain boundaries, dislocations, and the second phase. However, the intrinsic brittleness and the limited glass forming ability of metallic glasses greatly limit their industrial application. Thus, the optimization of the toughness of metallic glasses has become a hot issue in current research. In this paper, the preparation and toughness optimization of metallic glass films are reviewed. Meanwhile, the future development trend of metallic glass films are prospected.

-

Key words:

- metallic glass /

- physical vapor deposition (PVD) /

- toughness /

- element doping /

- interface

-

图 3 (a) S1、S2和S3非晶合金的压缩薄片;(b) S2非晶合金弯曲成不同形状,表现出特殊的变形能力;(c) S2非晶合金在不同标称应变下形变[13]

Figure 3. (a) Compressed sheets of S1, S2 and S3 amorphous alloys, (b) S2 amorphous alloy bends into different shapes, showing special deformation ability, (c) S2 amorphous alloy deforms under different nominal strains[13]

-

[1] DIYATMIKA W,CHU J P,KACHA B T,et al. Thin film metallic glasses in optoelectronic,magnetic,and electronic applications:a recent update[J]. Current Opinion in Solid State and Materials Science,2015,19(2): 95-106. doi: 10.1016/j.cossms.2015.01.001 [2] LIANG D D,WEI X S,CHANG C T,et al. Effect of W addition on the glass forming ability and mechanical properties of Fe-based metallic glass[J]. Journal of Alloys and Compounds,2018(731): 1146-1150. [3] LIANG D D,ZHOU Y H,LIU X D,et al. Wettability and corrosion performance of arc-sprayed Fe-based amorphous coatings[J]. Surface and Coatings Technology,2022(433): 128129. [4] LIANG D D,WEI X S,WANG Y,et al. Electrochemical behaviors and passive film properties of Fe-based bulk metallic glass in Cl−-containing acetic acid solutions under high temperature[J]. Journal of Alloys and Compounds,2018(766): 964-972. [5] KLEMENT W,WILLENS R H,DUWEZ P O L. Non-crystalline structure in solidified gold–silicon alloys[J]. Nature,1960,187(4740): 869-870. [6] INOUE A,ZHANG T,MASUMOTO T. Al–La–Ni amorphous alloys with a wide supercooled liquid region[J]. Materials Transactions JIM,1989,30(12): 965-972. [7] INOUE A,TAKEUCHI A. Recent development and application products of bulk glassy alloys[J]. Acta Materialia,2011,59(6): 2243-2267. doi: 10.1016/j.actamat.2010.11.027 [8] INOUE A,NEGISHI T,KIMURA H M,et al. High packing density of Zr-and Pd-based bulk amorphous alloys[J]. Materials Transactions JIM,1998,39(2): 318-321. [9] ZHAO K,WANG N,LI S,et al. Corrosion behavior of Ni62Nb33Zr5 bulk metallic glasses after annealing and cryogenic treatments[J]. ChemPhysMater,2023,2(1): 58-68. [10] SARAC B,IVANOV Y P,CHUVILIN A,et al. Origin of large plasticity and multiscale effects in iron-based metallic glasses[J]. Nature Communications,2018,9(1): 1333. doi: 10.1038/s41467-018-03744-5 [11] LEWANDOWSKI J J,WANG W H,GREER A L. Intrinsic plasticity or brittleness of metallic glasses[J]. Philosophical Magazine Letters,2005,85(2): 77-87. doi: 10.1080/09500830500080474 [12] WANG W H. Correlations between elastic moduli and properties in bulk metallic glasses[J]. Journal of Applied Physics,2006,99(9): 093506. doi: 10.1063/1.2193060 [13] LIU Y H,WANG G,WANG R J,et al. Super plastic bulk metallic glasses at room temperature[J]. Science,2007,315(5817): 1385-1388. doi: 10.1126/science.1136726 [14] LI M X,ZHAO S F,LU Z,et al. High-temperature bulk metallic glasses developed by combinatorial methods[J]. Nature,2019,569(7754): 99-103. doi: 10.1038/s41586-019-1145-z [15] LIU M C,LEE C J,LAI Y H,et al. Microscale deformation behavior of amorphous/ nanocrystalline multilayered pillars[J]. Thin Solid Films,2010,518(24): 7295-7299. [16] GUO W,JAGLE E A,CHOI P P,et al. Shear-induced mixing governs codeformation of crystalline-amorphous nanolaminates[J]. Physical Review Letters,2014,113(3): 035501. doi: 10.1103/PhysRevLett.113.035501 [17] KIMURA H,MASUMOTO T. A model of the mechanics of serrated flow in an amorphous alloy[J]. Acta Metallurgica,1983,31(2): 231-240. doi: 10.1016/0001-6160(83)90100-1 [18] TAO P , ZHANG W , CHEN Y,et al. Effect of high temperature deformation on the deformation behavior and thermodynamic properties of a Zr-based bulk amorphous alloy[J]. Thin Solid Films,2022,907: 164450. doi: 10.1016/j.tsf.2010.04.096 [19] SUN X,WU D,ZOU L,et al. Dislocation-induced stop-and-go kinetics of interfacial transformations[J]. Nature,2022,607(7920): 708-713. doi: 10.1038/s41586-022-04880-1 [20] MA C F,HUANG P,XU K W,et al. Free volume gradient effect on shear banding behavior in CuZr/CuZr multilayers[J]. Thin Solid Films,2018(666): 48-53. [21] KONTIS P,KöHLER M,EVERTZ S,et al. Nano-laminated thin film metallic glass design for outstanding mechanical properties[J]. Scripta Materialia,2018(155): 73-77. [22] WEI X,YING C,WU J,et al. Fabrication,corrosion,and mechanical properties of magnetron sputtered Cu-Zr-Al metallic glass thin film[J]. Materials,2019,12(24): 4147. doi: 10.3390/ma12244147 [23] LIU X,ZHOU J,WANG J,et al. Novel Ta46.5W35Co18.5 thin film metallic glass with excellent corrosion resistance,high hardness and good thermal stability[J]. Journal of Alloys and Compounds,2022(890): 161874. [24] KAUSHIK N,SHARMA P,AHADIAN S,et al. Metallic glass thin films for potential biomedical applications[J]. Journal of Biomedical Materials Research Part B:Applied Biomaterials,2014,102(7): 1544-1552. doi: 10.1002/jbm.b.33135 [25] DAS S,SANTOS-ORTIZ R,ARORA H S,et al. Electromechanical behavior of pulsed laser deposited platinum-based metallic glass thin films[J]. Physica Status Solidi (a),2016,213(2): 399-404. doi: 10.1002/pssa.201532639 [26] 陈传忠, 包全合, 姚书山, 等. 脉冲激光沉积技术及其应用[J]. 2003, 27(5): 443-446. [27] HUFNAGEL T C,SCHUH C A,FALK M L. Deformation of metallic glasses:recent developments in theory,simulations,and experiments[J]. Acta Materialia,2016(109): 375-393. [28] GEORGARAKIS K,ALJERF M,LI Y,et al. Shear band melting and serrated flow in metallic glasses[J]. Applied Physics Letters,2008,93(3): 031907. doi: 10.1063/1.2956666 [29] ZíTEK M,ZEMAN P,KOTRLOVá M,et al. Impact of Al or Si addition on properties and oxidation resistance of magnetron sputtered Zr-Hf-Al/Si-Cu metallic glasses[J]. Journal of Alloys and Compounds,2019(772): 409-417. [30] CHU J P,LIU C T,MAHALINGAM T,et al. Annealing-induced full amorphization in a multicomponent metallic film[J]. Physical Review B,2004,69(11): 113410. doi: 10.1103/PhysRevB.69.113410 [31] APREUTESEI M,STEYER P,BILLARD A,et al. Zr–Cu thin film metallic glasses:an assessment of the thermal stability and phases’ transformation mechanisms[J]. Journal of Alloys and Compounds,2015(619): 284-292. [32] ACHACHE S,SANCHETTE F. Effect of tantalum addition on properties of Cu–Zr–based thin film metallic glasses (TFMGs)[J]. Coatings,2020,10(6): 515. doi: 10.3390/coatings10060515 [33] ETIEMBLE A,DER LOUGHIAN C,APREUTESEI M,et al. Innovative Zr-Cu-Ag thin film metallic glass deposed by magnetron PVD sputtering for antibacterial applications[J]. Journal of Alloys and Compounds,2017(707): 155-161. [34] LAI J J,LIN Y S,CHANG C H,et al. Promising Ta-Ti-Zr-Si metallic glass coating without cytotoxic elements for bio-implant applications[J]. Applied Surface Science,2018(427): 485-495. [35] OAK J J,LOUZGUINE-LUZGIN D V,INOUE A. Fabrication of Ni-free Ti-based bulk-metallic glassy alloy having potential for application as biomaterial,and investigation of its mechanical properties,corrosion,and crystallization behavior[J]. Journal of Materials Research,2011,22(5): 1346-1353. [36] OAK J J,LOUZGUINE-LUZGIN D V,INOUE A. Investigation of glass-forming ability,deformation and corrosion behavior of Ni-free Ti-based BMG alloys designed for application as dental implants[J]. Materials Science and Engineering:C,2009,29(1): 322-327. [37] YU C C,LEE C M,CHU J P,et al. Fracture-resistant thin-film metallic glass:ultra-high plasticity at room temperature[J]. APL Materials,2016,4(11): 116101. doi: 10.1063/1.4966932 [38] HE S,LI Y,LIU L,et al. Semiconductor glass with superior flexibility and high room temperature thermoelectric performance[J]. Science Advances,2020,6(15): eaaz8423. doi: 10.1126/sciadv.aaz8423 [39] PARK E S,LEE J Y,KIM D H,et al. Correlation between plasticity and fragility in Mg-based bulk metallic glasses with modulated heterogeneity[J]. Journal of Applied Physics,2008,104(2): 023520. doi: 10.1063/1.2955715 [40] KIM D,KIM W,PARK E,et al. Phase separation in metallic glasses[J]. Progress in Material Science,2013,58(8): 1103-1172. doi: 10.1016/j.pmatsci.2013.04.002 [41] HOWE J M,SAKA H. In situ transmission electron microscopy studies of the solid–liquid interface[J]. MRS Bulletin,2004,29(12): 951-957. doi: 10.1557/mrs2004.266 [42] GLEITER H. Our thoughts are ours,their ends none of our own:are there ways to synthesize materials beyond the limitations of today?[J]. Acta Materialia,2008,56(19): 5875-5893. doi: 10.1016/j.actamat.2008.08.028 [43] FANG J,VAINIO U,PUFF W,et al. Atomic structure and structural stability of Sc75Fe25 nanoglasses[J]. Nano Letters,2012,12(1): 458-463. doi: 10.1021/nl2038216 [44] ŞOPU D,ALBE K,RITTER Y,et al. From nanoglasses to bulk massive glasses[J]. Applied Physics Letters,2009,94(19): 191911. doi: 10.1063/1.3130209 [45] GU H,LIU C,YUAN F,et al. Deformation twinning in octahedron-based face-centered cubic metallic structures: localized[J]. Journal of Materials Science and Technology,2022(34): 74-78. [46] ZHOU H F,ZHONG C,CAO Q P,et al. Non-localized deformation in metallic alloys with amorphous structure[J]. Acta materialia,2014,68: 32-41. doi: 10.1016/j.actamat.2014.01.003 [47] ZHONG C,ZHANG H,CAO Q,et al. Deformation behavior of metallic glasses with shear band like atomic structure:a molecular dynamics study[J]. Scientific Reports,2016,6(1): 30935. doi: 10.1038/srep30935 [48] LIANG D, LIU X, ZHOU Y, et al. Effects of annealing below glass transition temperature on the wettability and corrosion performance of Fe-based amorphous coatings[J]. Acta Metallurgica Sinica (English Letters), 2022: 1-11. [49] LIANG D,TSENG J C,LIU X,et al. Investigation of the structural heterogeneity and corrosion performance of the annealed Fe-based metallic glasses[J]. Materials,2021,14(4): 929. doi: 10.3390/ma14040929 [50] LIANG D,MA J,CAI Y,et al. Characterization and elevated-temperature tribological performance of AC–HVAF-sprayed Fe-based amorphous coating[J]. Surface and Coatings Technology,2020(387): 125535. [51] CHOU H S,DU X H,LEE C J,et al. Enhanced mechanical properties of multilayered micropillars of amorphous ZrCuTi and nanocrystalline Ta layers[J]. Intermetallics,2011,19(7): 1047-1051. doi: 10.1016/j.intermet.2011.03.015 [52] ZHANG J Y,LIU Y,CHEN J,et al. Mechanical properties of crystalline Cu/Zr and crystal–amorphous Cu/Cu–Zr multilayers[J]. Materials Science and Engineering:A,2012(552): 392-398. [53] HUANG H S,PEI H J,CHANG Y C,et al. Tensile behaviors of amorphous-ZrCu /nanocrystalline-Cu multilayered thin film on polyimide substrate[J]. Thin Solid Films,2013(529): 177-180. [54] GLUSHKO O,GAMMER C,WENIGER L M,et al. Morphology of cracks and shear bands in polymer-supported thin film metallic glasses[J]. Materials Today Communications,2021(28): 102547. [55] SCHUH C A,HUFNAGEL T C,RAMAMURTY U. Mechanical behavior of amorphous alloys[J]. Acta Materialia,2007,55(12): 4067-4109. doi: 10.1016/j.actamat.2007.01.052 [56] KIM J Y,JANG D,GREER J R. Nanolaminates utilizing size-dependent homogeneous plasticity of metallic glasses[J]. Advanced Functional Materials,2011,21(23): 4550-4554. doi: 10.1002/adfm.201101164 [57] KABAN I,JóVáRI P,KOKOTIN V,et al. Local atomic arrangements and their topology in Ni–Zr and Cu–Zr glassy and crystalline alloys[J]. Acta Materialia,2013,61(7): 2509-2520. doi: 10.1016/j.actamat.2013.01.027 [58] LANGER J. Shear-transformation-zone theory of deformation in metallic glasses[J]. Scripta Materialia,2006,54(3): 375-379. doi: 10.1016/j.scriptamat.2005.10.005 [59] ZHOU Q,LUO D,YE W,et al. Mechanical and tribological behaviors of metallic glass/ graphene film with a laminated structure[J]. Composites Part A:Applied Science and Manufacturing,2022(155): 106851. -

下载:

下载:

地址:上海市漕宝路120号

地址:上海市漕宝路120号 电话:021-64691562

电话:021-64691562  邮箱:

邮箱: 版权所有:《应用技术学报》编辑部

版权所有:《应用技术学报》编辑部